To compete in an increasingly challenging environment, the industrial sector needs to find new ways to optimize asset value and performance.

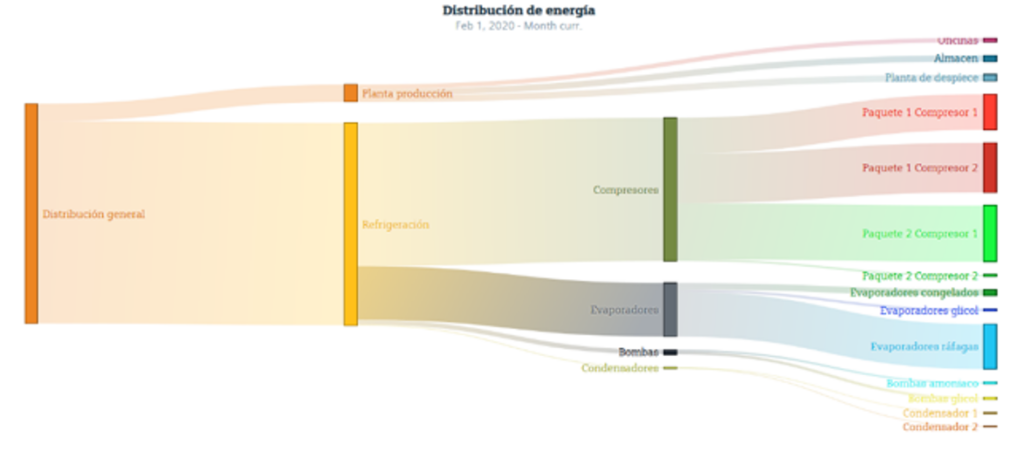

VYDRA‘s digital platform takes advantage of the data generated within our clients’ facilities to analyze and transform it into knowledge, allowing us to generate energy transparency to convert it into energy efficiency, increase asset availability, optimize maintenance intervals and improve system performance.

Provides information on how much and where you should spend your money.

The evaluation includes: standardization, characterization, transparency, anomaly detection and benchmarking.

Sensors, meters and machines are used to collect data for evaluation on the platform.

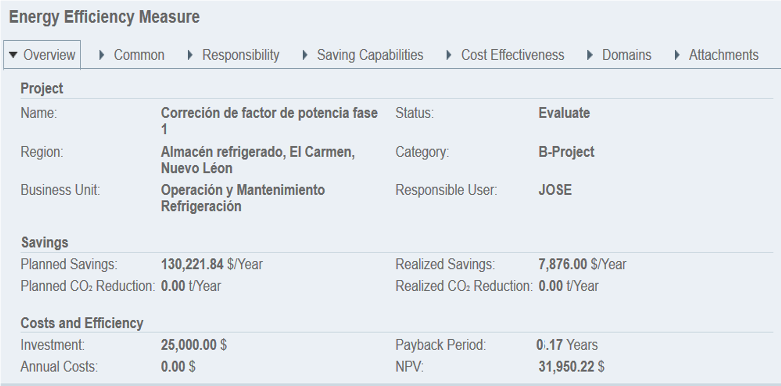

Implementation of efficiency measures for energy savings and efficiency with mapping, follow-up and real impact monitoring of the implemented measures.